The Strong and Versatile Expanded Metal Every Builder Should Know

Posted by A1 Metal Mesh on 12th Nov 2025

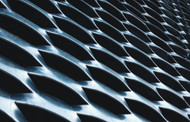

When it comes to materials that combine durability, functionality, and design appeal, few can match the versatility of expanded metal. From heavy-duty industrial walkways to striking architectural facades, expanded metal plays a crucial role in modern construction across Australia. Yet many builders and designers still overlook how valuable and adaptable this material really is.

This article explores what expanded metal is, how it’s made, and why it’s become a trusted choice among builders, fabricators, and architects.

What Is Expanded Metal?

Expanded metal begins as a solid sheet of metal (most commonly steel, aluminium, or stainless steel) that is simultaneously slit and stretched through an industrial press. This process forms a pattern of diamond-shaped openings without wasting material or requiring any welding. The result is a mesh that is lightweight yet incredibly strong.

Because expanded metal is produced from a single piece of metal, it maintains its structural integrity and resists unravelling or fraying. This makes it ideal for applications where safety and durability are paramount, such as platforms, security screens, or fabrication structures.

Why Builders Prefer Expanded Metal

Builders choose expanded metal for good reason. It offers a unique combination of strength, flexibility, and cost-effectiveness that few other materials can deliver.

- Strength and Stability: Despite its open design, expanded metal retains the strength of the parent sheet. The bonds where the strands intersect distribute weight evenly, allowing it to handle heavy loads and withstand stress.

- Slip Resistance: The raised surface provides natural grip, making it perfect for walkways, stair treads, and mezzanine flooring.

- Ventilation and Light: The diamond pattern allows air, light, and sound to pass through freely, which improves safety, comfort, and energy efficiency.

- Aesthetic Appeal: Beyond its practicality, expanded metal adds a textured, modern look to architectural projects, giving buildings a sleek and industrial finish.

According to the Australian Bureau of Statistics, the construction sector remains one of the nation’s largest industries, contributing over 8 percent of Australia’s GDP. As more builders focus on sustainable and long-lasting materials, expanded metal has become an increasingly popular choice.

Common Applications of Expanded Metal

One of the reasons expanded metal is so popular is its incredible adaptability. It can be used in a wide range of projects, from large-scale industrial sites to creative interior designs.

1. Walkways and Platforms

The high strength-to-weight ratio of expanded metal makes it a safe, reliable option for platforms and catwalks. Its slip-resistant surface enhances safety in areas exposed to moisture or oil.

2. Security and Fencing

Expanded metal is tough to cut or deform, providing excellent security for commercial sites, warehouses, and public spaces. It can also be used for gates and protective cages.

3. Architectural Design

Architects use expanded metal to create dramatic façades, sunscreens, and privacy panels. It allows for airflow and filtered light while adding depth and texture to modern designs.

4. Filtration and Screening

The open pattern of expanded metal is perfect for filtration systems, machine guards, and ventilation grilles.

5. Reinforcement and Support

In construction, expanded metal mesh is often used as reinforcement for plaster or structural support, ensuring a stronger finished product.

Choosing the Right Type of Expanded Metal

Selecting the right type of expanded metal depends on how it will be used. At A1 Metal Mesh, customers can choose from various materials, thicknesses, and patterns to suit their exact project requirements.

Material Options:

- Mild Steel: Strong and economical, ideal for structural and security uses.

- Stainless Steel: Resistant to corrosion, suitable for outdoor and marine environments.

- Aluminium: Lightweight and easy to handle, perfect for decorative or non-load-bearing applications.

Pattern and Size:

The size of the diamond openings determines strength, airflow, and visibility. Smaller meshes provide security or filtration, while larger ones reduce weight and improve transparency.

Finishes and Coatings:

Expanded metal can be galvanised, powder-coated, or anodised for added durability and visual appeal. These finishes enhance corrosion resistance, particularly in Australia’s coastal and high-humidity environments.

Advantages of Expanded Metal Over Other Meshes

Compared with welded or perforated metal mesh, expanded metal offers several distinct advantages:

- No Waste: The process stretches the original sheet without punching out excess material, making it efficient and eco-friendly.

- No Welds or Weak Points: Expanded metal is a single, continuous piece, which means it won’t split or separate under stress.

- Cost-Effective Coverage: One sheet of expanded metal covers more area than its solid counterpart, lowering overall material costs.

- Ease of Fabrication: It can be cut, bent, or shaped without compromising its structure.

These benefits make expanded metal one of the most reliable and economical materials available in construction and manufacturing today.

How Expanded Metal Supports Sustainable Building

Sustainability is becoming increasingly important in Australian construction, and expanded metal aligns perfectly with that trend. Because it involves minimal waste during production and can be made from recycled metals, it contributes to more resource-efficient building practices.

Its long lifespan also reduces replacement costs and environmental impact over time. Expanded metal’s ability to provide natural ventilation and light can further enhance energy efficiency in buildings, especially when used for shading or façade systems.

Tips for Working with Expanded Metal

For builders and fabricators new to expanded metal, a few best practices ensure optimal results:

- Measure and plan cutting layouts carefully to minimise waste.

- Use protective gloves and proper tools, as edges can be sharp after cutting.

- Choose the right coating for your environment to extend the product’s life.

- When installing large panels, allow for slight expansion and contraction in outdoor settings.

If in doubt, consult your supplier for technical guidance before installation.

Why Choose A1 Metal Mesh

With decades of experience supplying high-quality metal mesh products across Australia, A1 Metal Mesh is a trusted partner for builders, architects, and manufacturers. The company offers a wide range of expanded metal options in different materials, patterns, and finishes, all manufactured to meet Australian standards.

Whether you’re constructing a factory walkway, designing a feature wall, or reinforcing a structure, A1 Metal Mesh can help you find the right product for your needs.

Choosing the right expanded metal isn’t just about strength; it’s about building safety, durability, and design excellence. At A1 Metal Mesh, we provide tailored mesh solutions that meet the demands of Australian construction and design projects. Contact us today to discuss your next project and discover how expanded metal can transform your build.